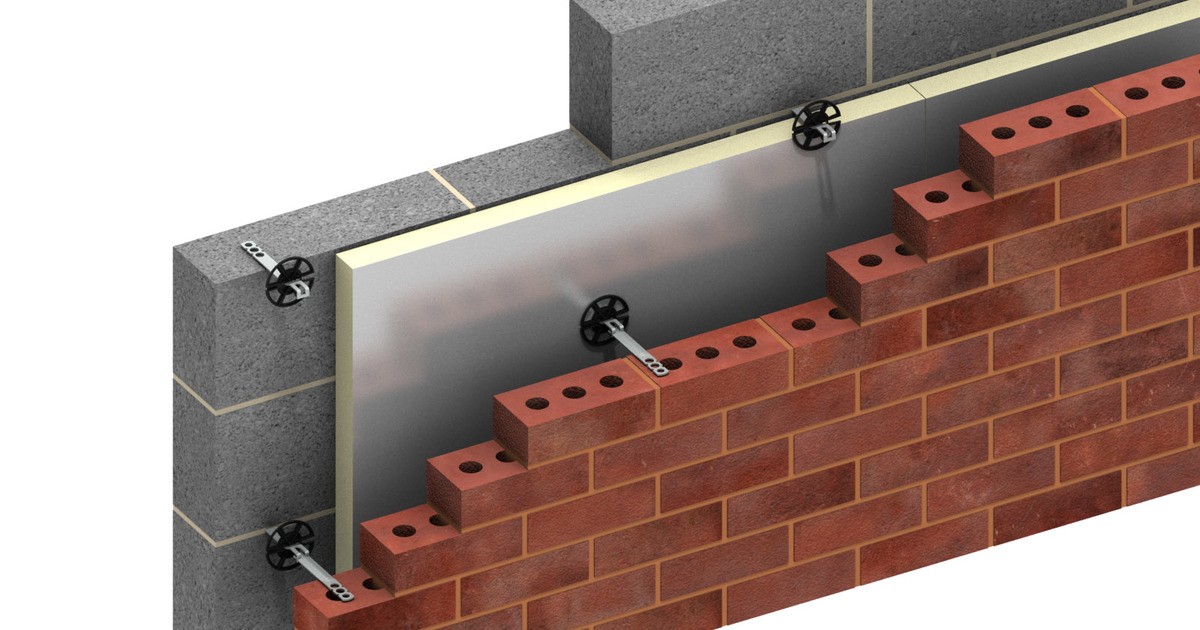

Cavity wall walls relate to concealed ties, sometimes known as ‘brick ties’ in construction. They are used to connect the two leaves of a cavity wall, allowing them to function as a single unit. Wall ties, which are hidden from view after installation, contribute greatly to the stability of a structure.

Wall ties are important structural components that can cause problems if they aren’t installed correctly, including damp penetration, masonry cracks, and even the outer leaf’s collapse. Wall ties are made of corrosion-resistant materials and have a drip formation to prevent water from seeping into the inner leaf.

Wall tie design

Cavity walls have been used in most buildings constructed since the 1920s. Tie shapes have altered considerably over the years, and materials like as plastic and galvanized steel are no longer utilized. Prior to 1978, wall ties were generally made of galvanized mild steel. These ties were supposed to endure the duration of the building, but it is now acknowledged.

Today, wall ties are made mostly of stainless steel, which is readily available commercially and protects against water and cement corrosion without the need for additional protection. Modern stainless steel wall ties have a long-lasting life without requiring maintenance and are value-engineered to save money.

In some cases, composite materials are employed, such as Ancon’s Teplo line of ties, which are composed of pultruded basalt fibres set in a resin matrix and are excellent for ultra-low energy construction because of their low thermal conductivity.

Wall tie installation

In normal brick-to-block construction, wall ties are inserted into the leaves during the build. Wall ties should be pressed down and then surrounded by fresh mortar before being pushed into a pre-existing connection to ensure that they are effective at tying the leaves together. They should be installed with a small slope to the outer leaf, not toward the inner leaf, since this may allow moisture to permeate through the gap. The drip part of the tie should point downward and be positioned near to but not within the open cavity’s centre.

Wall ties are often used in other forms of cavity wall construction, such as thin-joint blockwork and timber or steel frames. After the inner leaf is built, they’re generally put in place during the outer leaf’s masonry construction.

Wall tie length and wall tie spacing

To span the cavity and provide the required embedment in the mortar at both ends, ties must be long enough to extend 62-75mm past the cavity. Consider a 200mm long wall tie for cavities ranging from 50 to 75 millimetres wide. Cavities are growing increasingly wider to accommodate thicker insulation depths as energy efficiency standards improve. Tie lengths of up to 450mm are now available to match cavity widths ranging from 50mm to 450mm.

The minimum density of cavity wall ties (as specified in Eurocode 6) is 2.5 ties per m2. They are generally put at 900mm horizontal and 450mm vertical space, with the gaps between them being 150 mm apart to provide an even coverage. One additional tie should be used for every 300mm height around openings and unbonded edges, plus one more tie per 100mm width along walls (however blockwork coursing usually implies that they are installed at 225mm vertical spacing). Additional information on the position and density of cavity wall ties may be found in PD 6697:2010.

900mm x 450mm centres in a staggered pattern (2.5 ties per square metre) Vertical and horizontal space for cavity brickwork 900mm x 450mm centres in a staggered arrangement (2.5 ties per square metre)

Wall tie selection

The type of wall tiles to be used is determined by a number of criteria. The kind and height of the building and its geographical location are examples of variables that may influence selection.

Several Eurocodes and Building Regulations cover all aspects of wall tie installation in any given situation, which should be researched and followed. In the United Kingdom, we have a separate Published Document (PD 6697:2010) that aids in the selection of wall ties based on geographical and topographic conditions to complement the Building Regulations and Eurocodes. This implies that cavity wall ties may be chosen without the aid of a structural engineer in most situations.

If you’re looking for more information about Wall Ties, Atlantis Damp, have a whole pleather of information available online. Why not check out their website to learn more.